Disassemble Your 3D Printer

Prerequisites- Basic Knowledge of 3D printing, How to Train your Printer Intro

⚠ WARNING: This article is part of an in-progress multipart series about building and tuning an Ender-3 3D printer. This contents of this article encourage you to disassemble your printer in preparation for inspecting the goodness of the individual components. The guidelines provided here are not "step-by-step" instructions and require proper judgement and maturity to follow.

⚠ SAFETY WARNING: Disconnect the printer from all electrical sources before disassembly. Ensure that all hot surfaces are cool before disassembly. Failure to follow these guidelines may result in shock, burns, injury, and even death.

Mechatronics.studio is not liable for any damage (personal or property) that results due to printer disassembly.

This article is intended to provide basic guidelines on preparing an Ender-3 (kit or fully-constructed) for detailed inspection. The general guidelines here apply to other printer types as well but printers with significant architecture differences (delta, coreXY, etc.) will require different levels of disassembly and inspection.

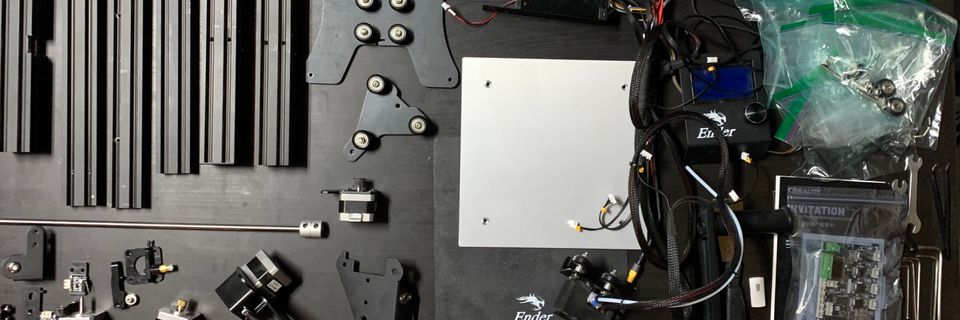

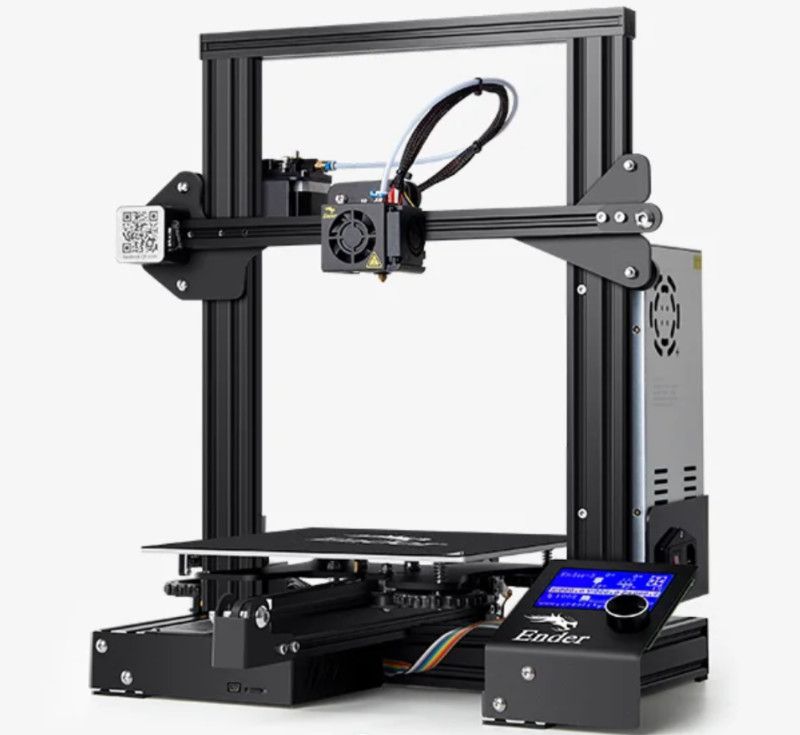

When preparing an Ender-3 for detailed part inspection you will likely start from either an Ender-3 kit or a fully-constructed Ender-3, as shown in Figure 1.

Figure 1: Images courtesy of Creality, Left- Ender-3 kit contents | Right- Fully-constructed Ender-3

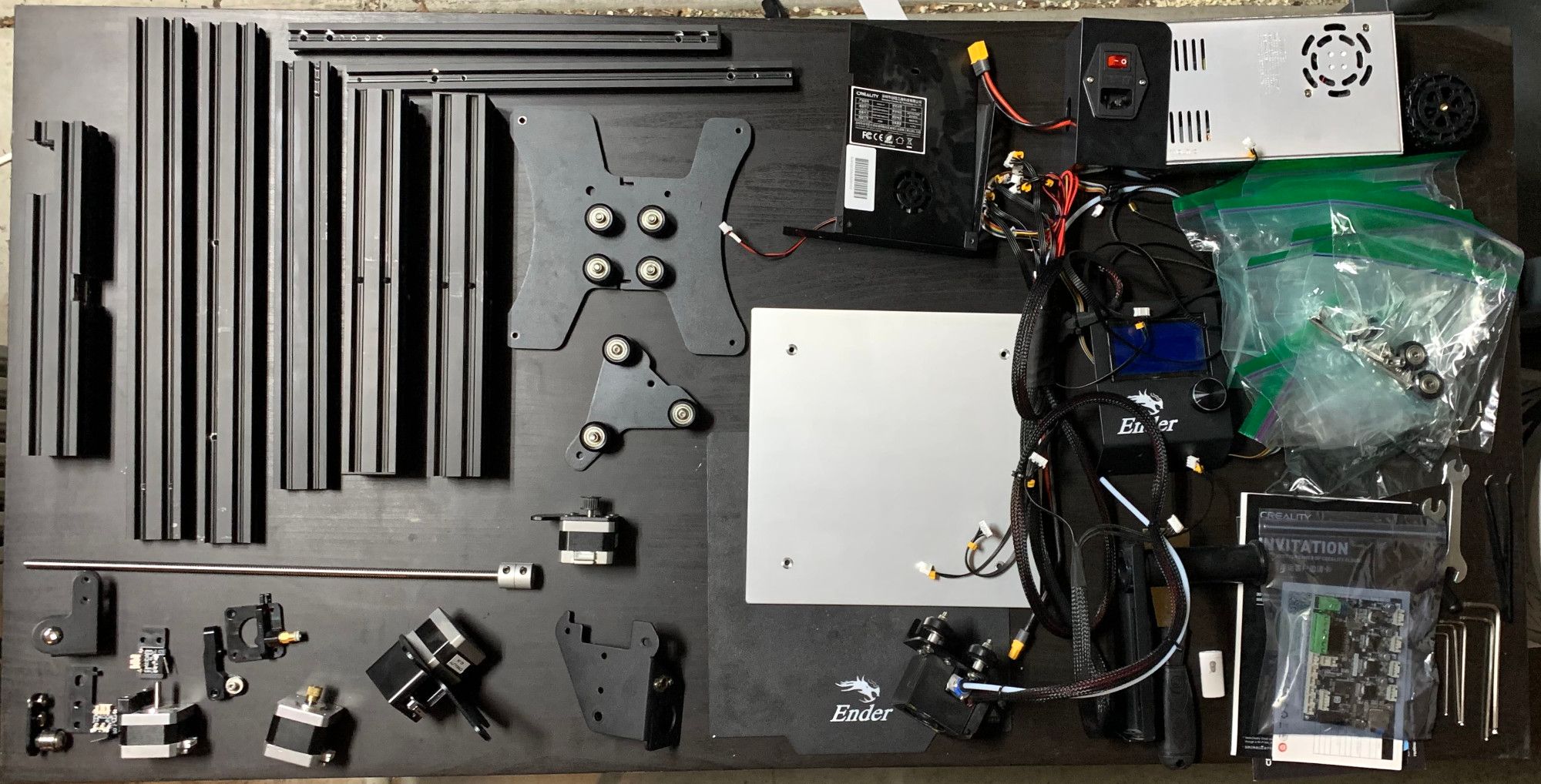

Regardless of whether you start with a kit or an assembled unit, substantial disassembly is needed to prepare the printer for inspection. The general principle is to fully isolate all linear motion related components for independent inspection. For the Ender-3, this means the following level of disassembly must be achieved:

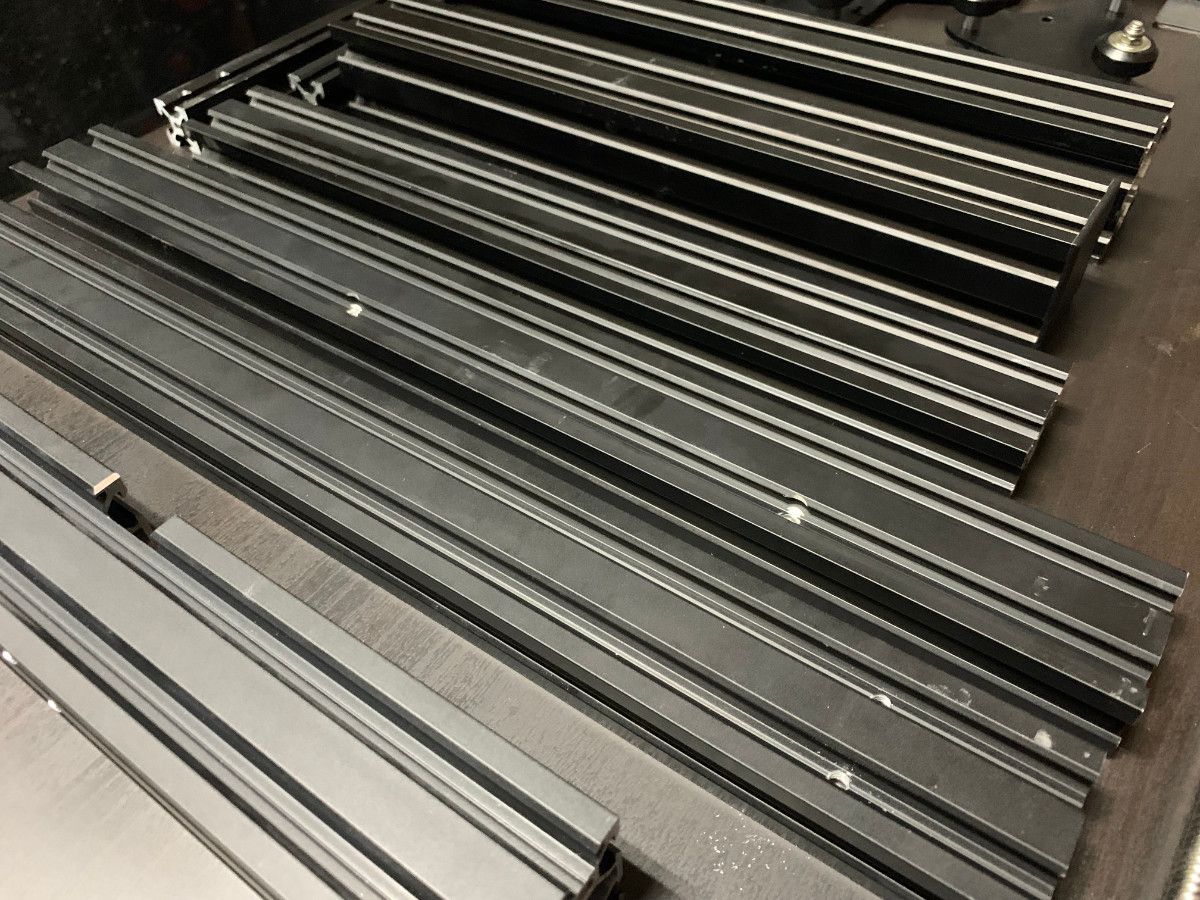

- The four aluminum extrusions that serve as linear guides must be fully isolated; these consist of the X and Y extrusions along with both Z upright extrusions. I also recommend disassembly of the base extrusions in preparation for assembling them square, which will make square assembly of the linear guide extrusions easier.

- The extruder bracket with the lead screw nut mounted to it must be isolated.

- All rollers must be accessible and spin freely.

- The leadscrew must be free and independent of the base.

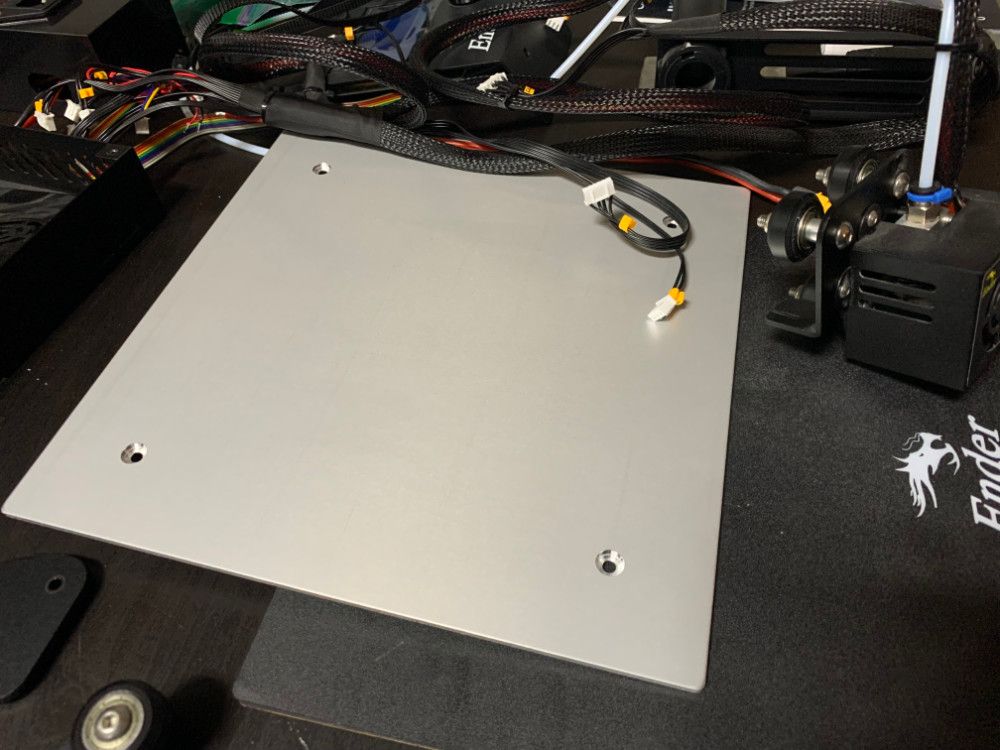

- The aluminum print bed (with heater adhered to the bottom) must be isolated from the Y-axis carriage. The build surface does not need to be removed from the print bed if it is adhered. The main wire harness is adjoined to both the print bed heater and the print head so the two will remain loosly connected by the harness.

Figure 2: Fully disassembled Ender-3 ready for inspection

Figure 3:Upper Left- Extruder Bracket | Upper Center- Y-axis carriage | Upper Right- Right Z-axis carriage | Lower Left- Aluminum extrusions | Lower Right- Build plate and print head

Note that the state of assembly for this inspection is less than the state the Ender-3 is in when it comes in the kit. Therefore, there are NO publicly facing directions for reassembling the printer from the individual parts. This is not a "step-by-step" guide and further, by forcing you to disassemble your printer in an organized and responsible manner, you are better prepared to effectively disassemble products in the future without a guide. It is very common in industry to disassemble and rebuild existing products to learn about them.

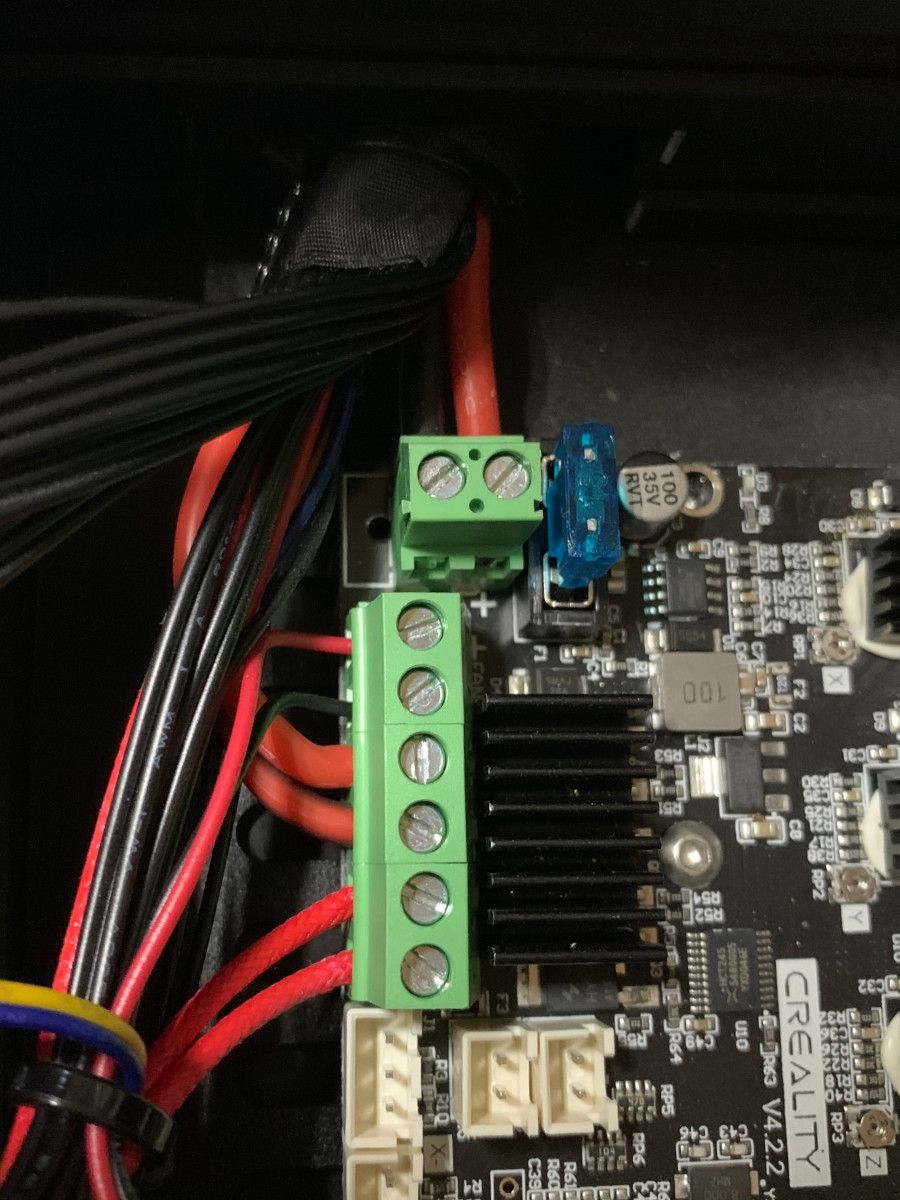

⚠ PART PROTECTION WARNING: Before handling the main printed circuit board, you should touch a grounded metal surface (like the exposed metal enclosure of a grounded household appliance) to discharge the static electricity from your body.

⚠ PART PROTECTION WARNING: Electrical connectors may be hot glued together. Carefully remove hot glue with pliers or trimmers. Failure to do so may result in damage to the wire harnesses or PCBA connectors.

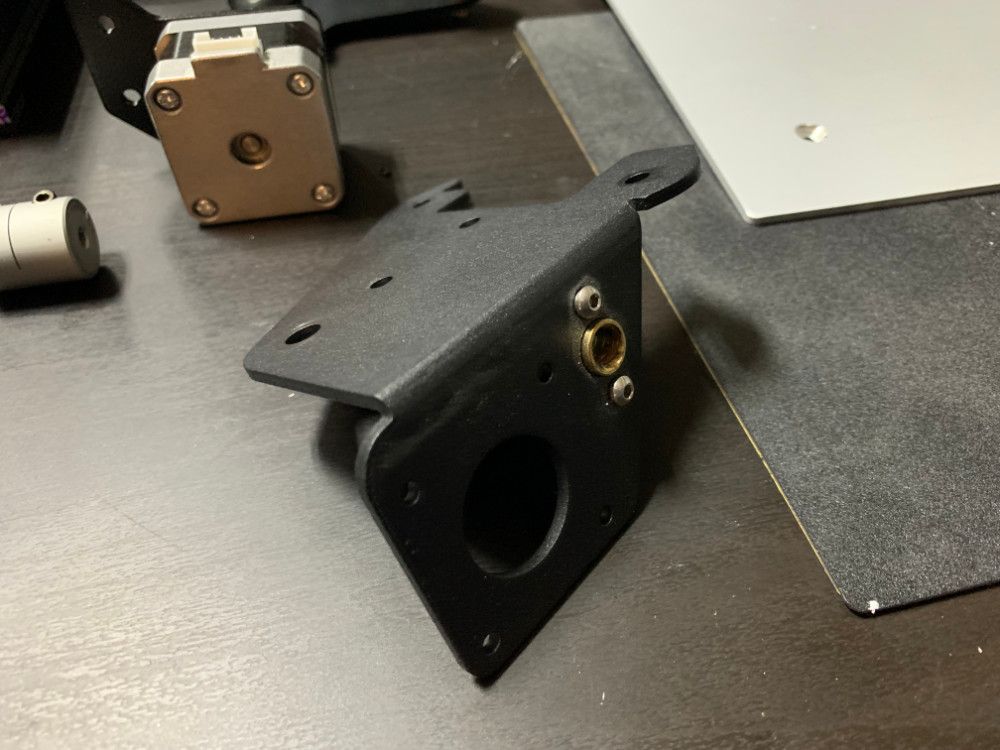

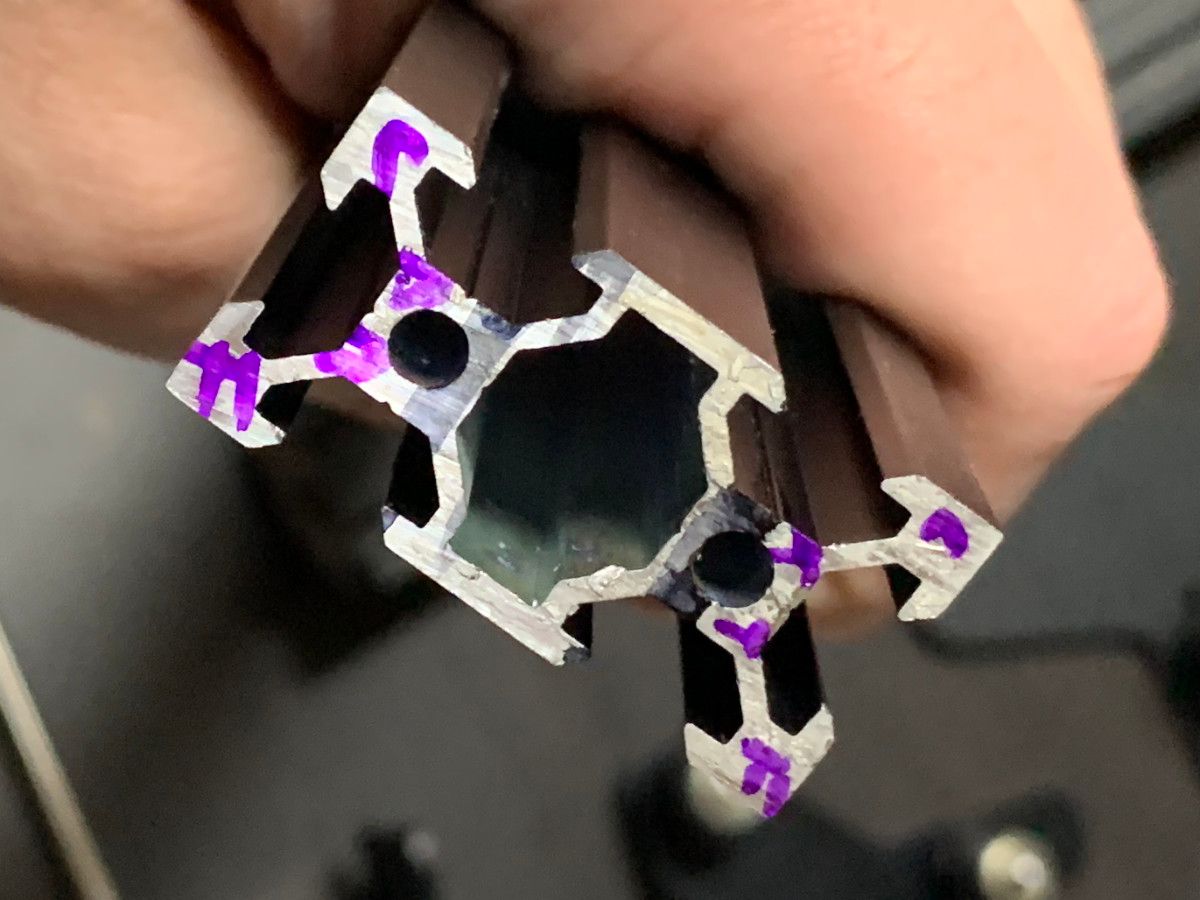

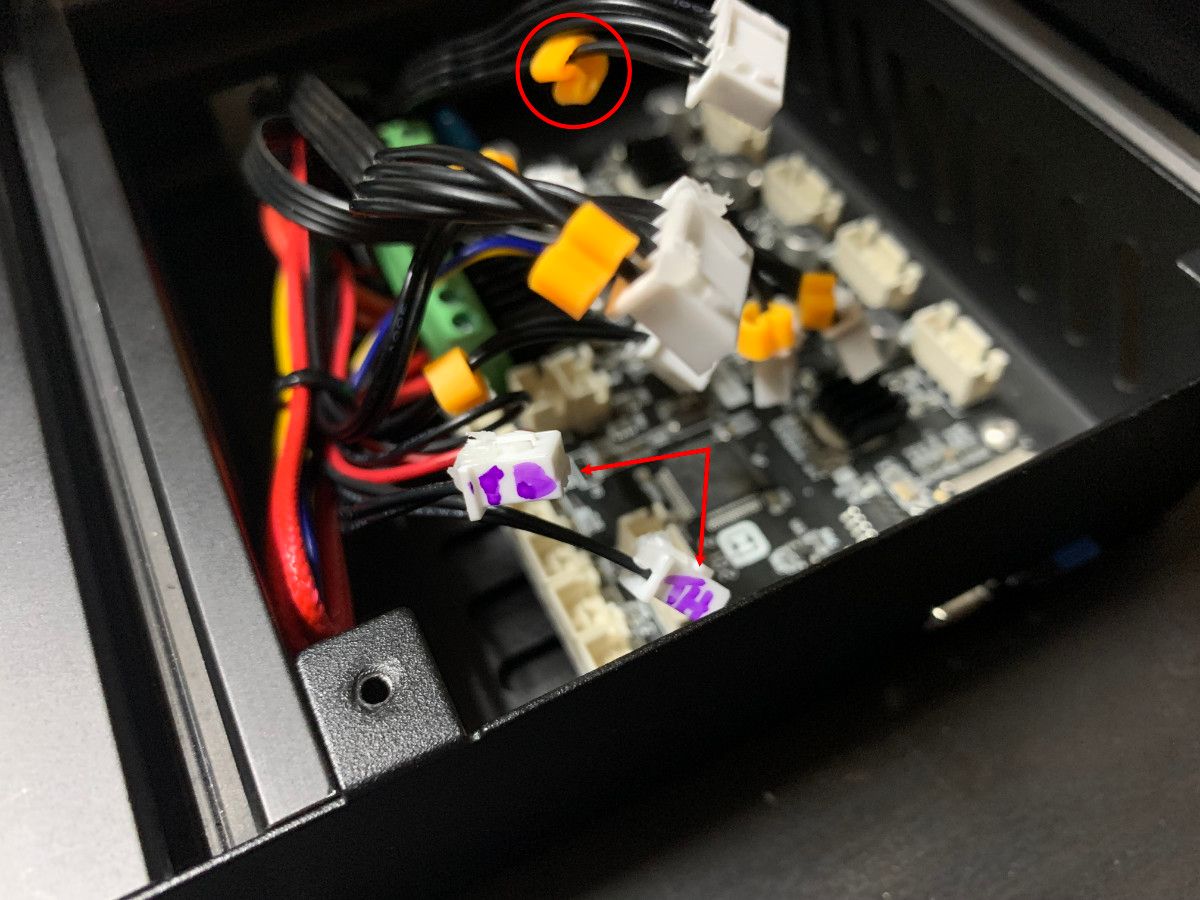

During disassembly, I strongly recommend a combination of photos and part marking to be certain that you can put the machine back together. The 3D model is a very helpful source for putting the larger mechanical components back together. In figure 4, I provide some recommendations that will make reassembly of the printer easier.

Ready? Good luck!

Figure 4:Upper Left- Unlabled wires differentiated by size or color can be documented using a camera. | Upper Center- The orientation information of extrusions can be labeled on the end. | Upper Right- Electronic boards should be placed into an antistatic bag to protect them from static shocks. | Lower Left- Some wire bundles have labeled tags on them (circled in red) while others need to be labeled (shown with purple marker) to avoid wire tracing during reassembly. | Lower Right- Screws and hardware should be placed in bags, sorted by type or by subassembly. Labeling the bags is highly recommended.