Improving a Portable Metal Stock Cutting Setup

This article is about a couple of improvements I tried to make (one was successful, one was not) to my portable bandsaw setup that I use to cut bar stock. I think these two exercises are interesting applications of using 3D printing to make quality of life improvements in a workshop.

Introduction

When machining metal, one needs some metal, preferably at about the right size of the part to avoid excessive waste. This seems pretty straightforward except for one issue... metal typically comes in long bars.

If a piece of metal stock didn't come as long bar, then likely somebody cut it for you. Having someone cut your metal stock is really inefficient, for two reasons:

- To always have someone cut your metal stock, you would need to know the size of what you want to machine every time you order metal.

- Having someone else cut your metal stock is quite expensive (it's uncommon because machine shops generally do it themselves).

My shop occupies half of a two-car garage (the other half of the garage is reserved for my wife's car) and inside I have a CNC mill, several 3D printers, a large laser cutter, my working desk, and more! Not a lot of extra room...

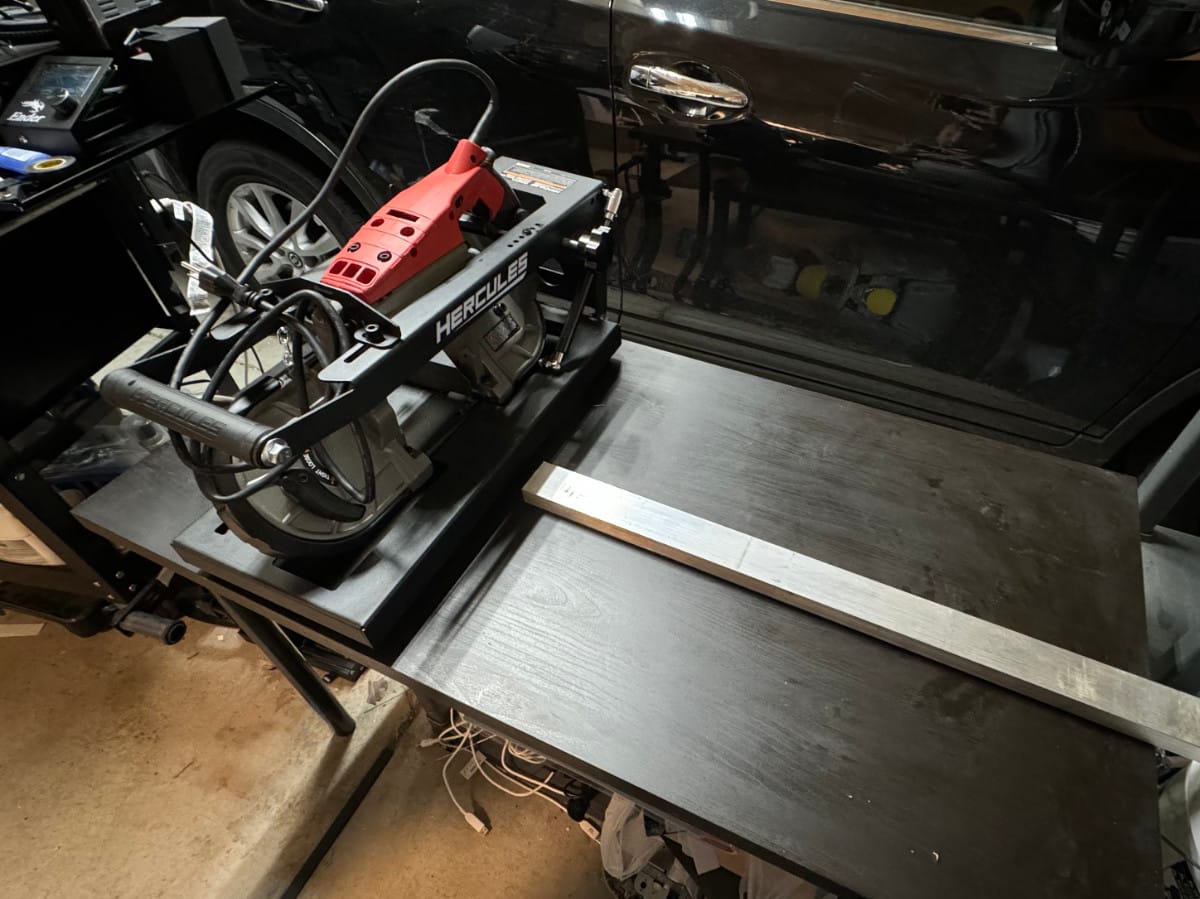

To cut metal to rough size myself, I have a portable bandsaw and stand that makes it possible to cut my metal on my main workbench.

The setup is actually quite effective except for two problems; height mismatch and a mess of chips. In the next two sections, I describe how I attempted to alleviate these challenges using 3D printed parts.

Height Mismatch

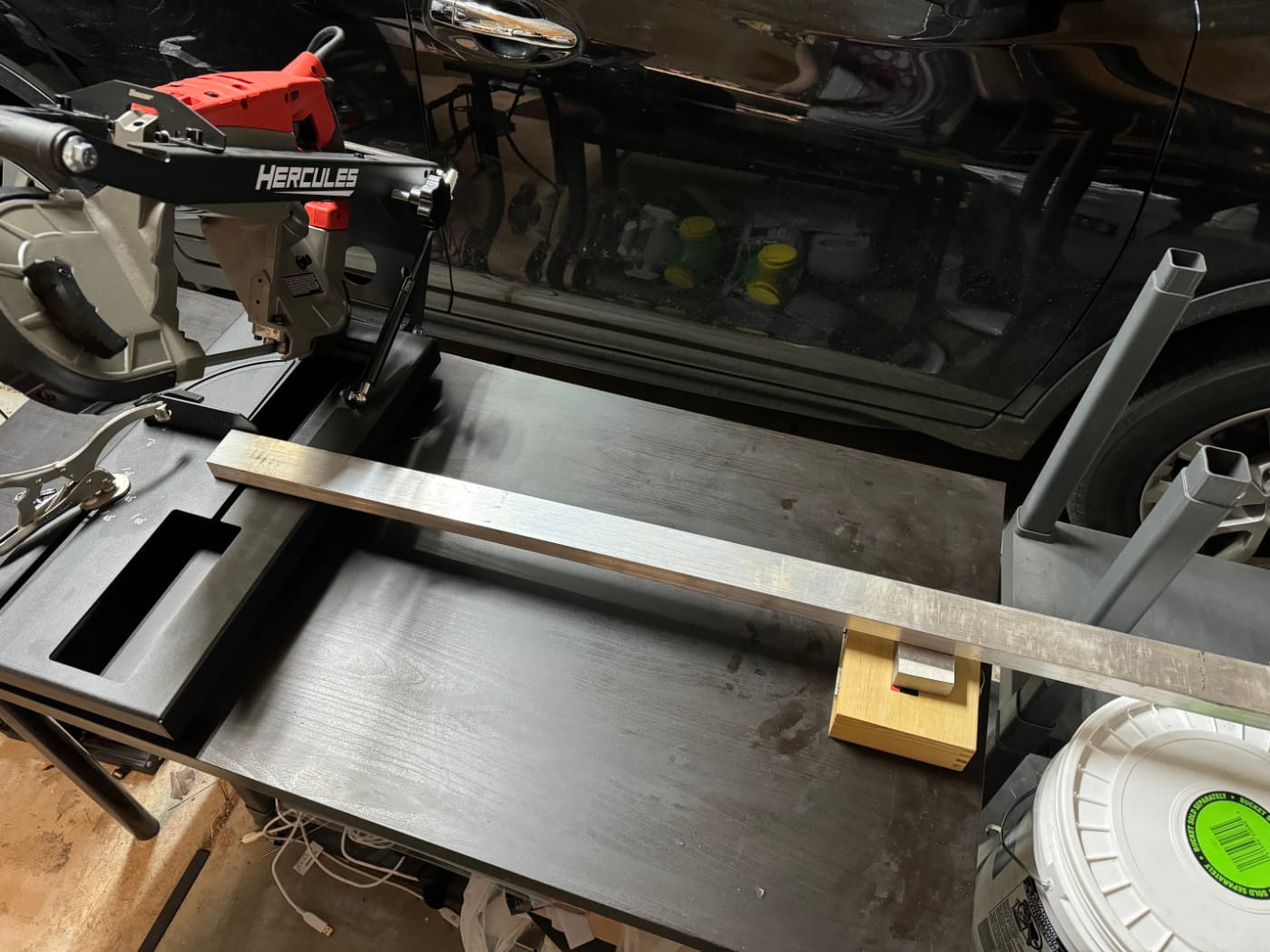

The saw sits above the table, which requires some sort of end support so that the beam lies flat on the saw. Height misalignment results in the material binding onto the saw as it gets cut or a very crooked cut.

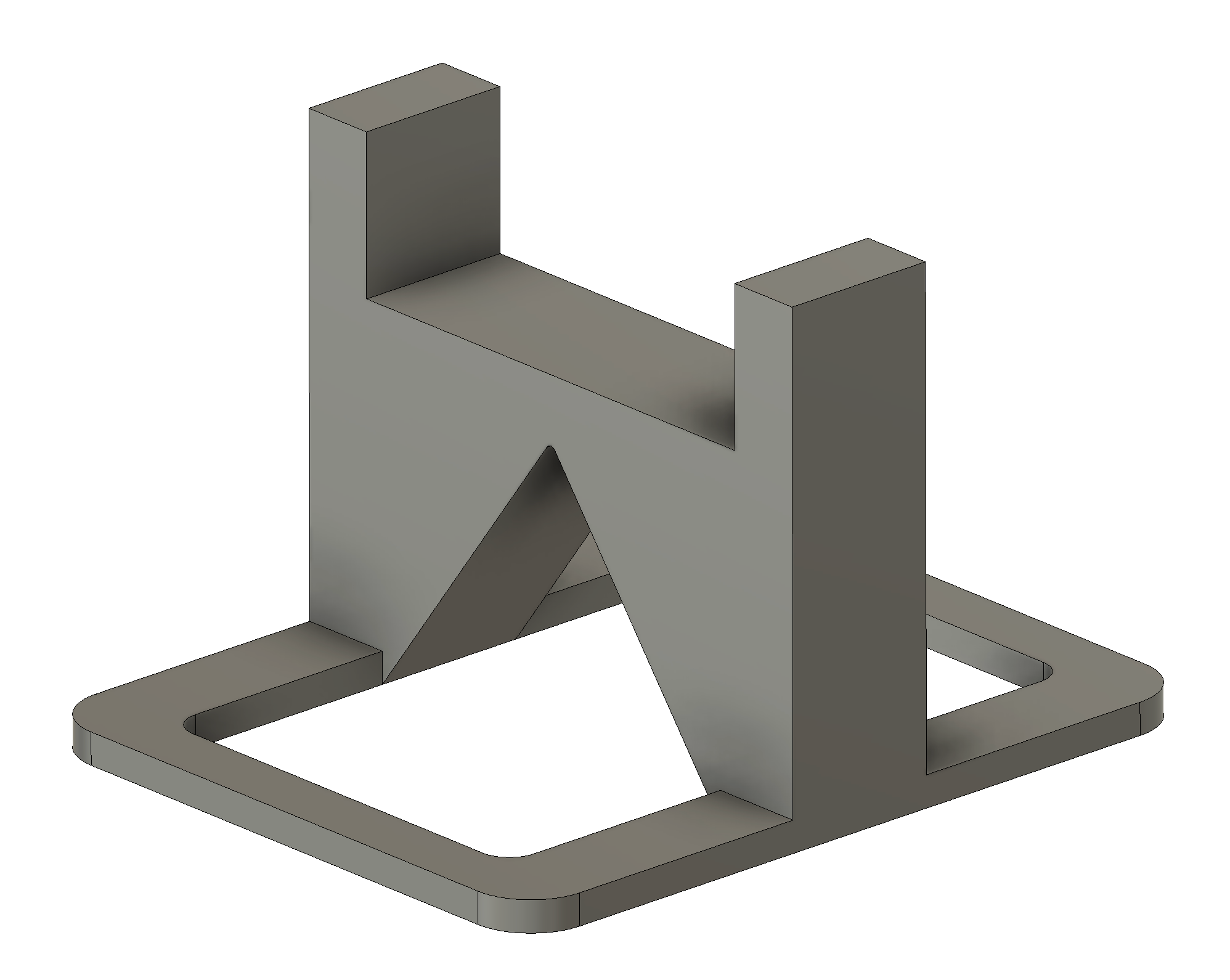

To resolve this, I designed and printed a few very simple stands to hold the end of the material at the correct height above the table.

Figure 4: Left- Model for 3D printed bar stock height adjustment. | Right- Bar stock height adjustors being printed.

After the print was complete, I tried them out and was generally pleased with their function. It will be great to have a dedicated tool for this.

Mess of Chips

The saw is right next to my wife's car, and when cutting metal it shoots chips everywhere; onto the table, onto the floor, under the saw, etc.

Figure 6: Demonstration of chip mess made by the cutting process (look closely at the table near the saw)

I normally clean chips up with a shop vac, but it would be nice if I could create a vacuum attachment for my saw that would at least reduce the mess of chips. Cue 3D printer.

The idea is simple. Create a part that hangs onto the saw and holds the vacuum hose while I am cutting.

3D printing is highly iterative, so I decided to split the design into two parts. First make the hanger, then add the hose holder.

After measuring the saw dimensions with calipers, I made a model and printed it. It took two two iterations of the dimensions to obtain a proper fit.

Figure 7: Left- Hanger design | Center- Printed Hanger | Right- Installation of hanger

After the hanger was dialed in, I added the vacuum hose adapter.

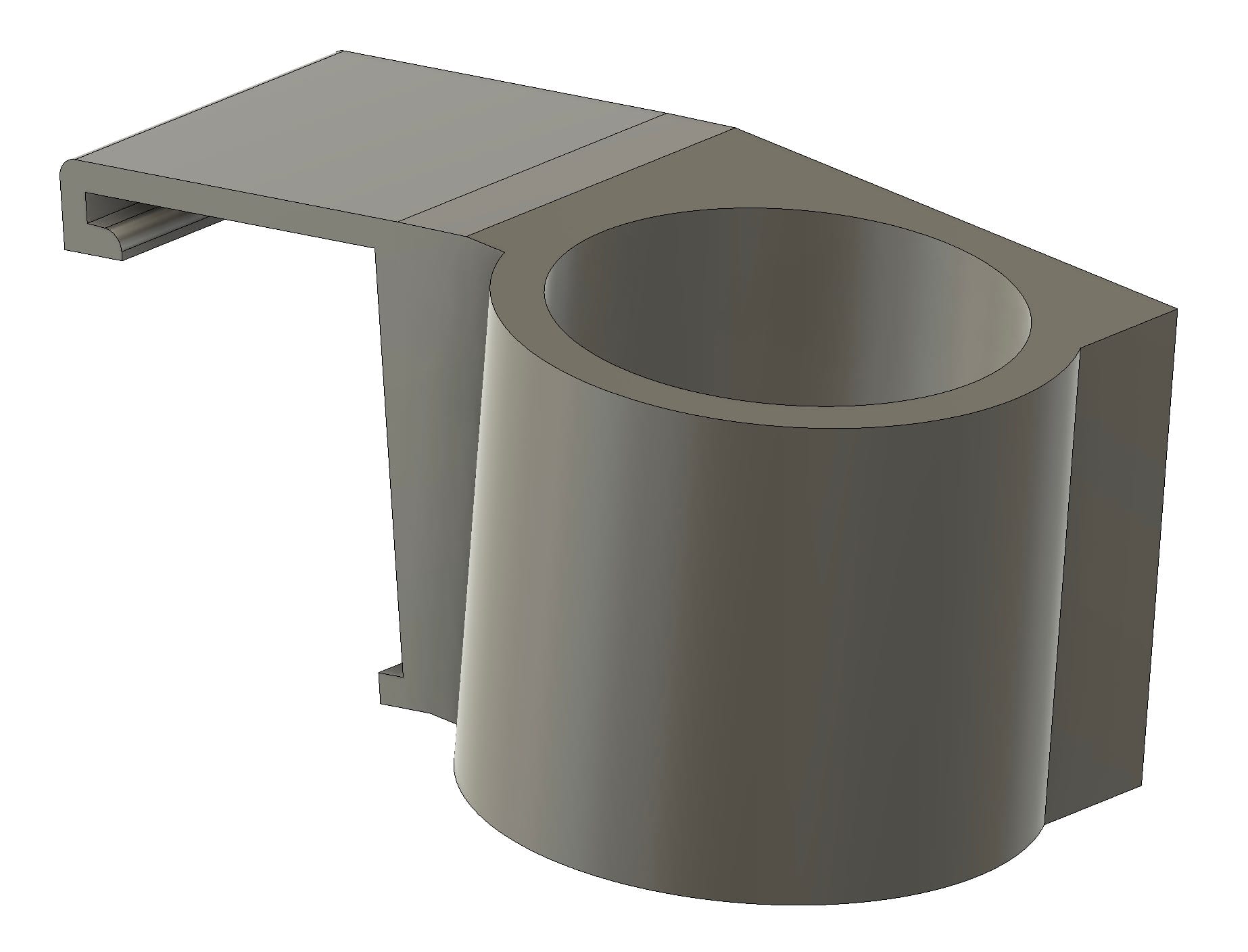

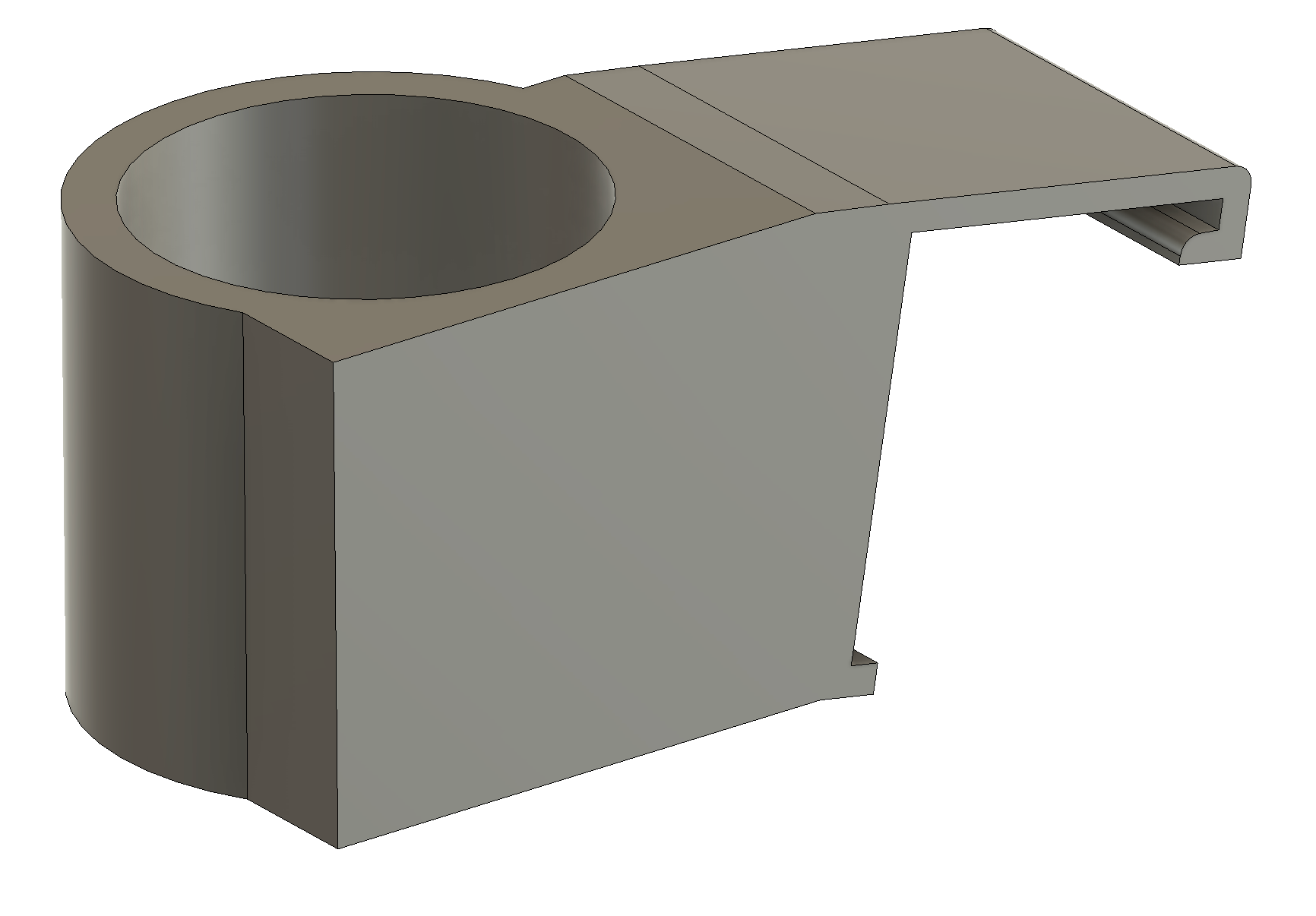

Figure 8: Two views of the hanger with vacuum hose attachment designed.

Observe how the back of the part is entirely flat, making it printable without support material (there is a resulting reduction in surface quality inside the vacuum holding bore).

Figure 9: Left- Sliced 3D model | Right- Vacuum adapter being printed

The end result is a well fitting bracket that successfully holds the end of the vacuum near the business end of the bandsaw.

Figure 10: Fit check of vacuum adapter

Unfortunately, though the design held the vacuum close to the workpiece, there was not enough suction to collect the chips.

I'm going to need to try a much more radical approach if I'm going to actually prevent the spread of chips from the saw.