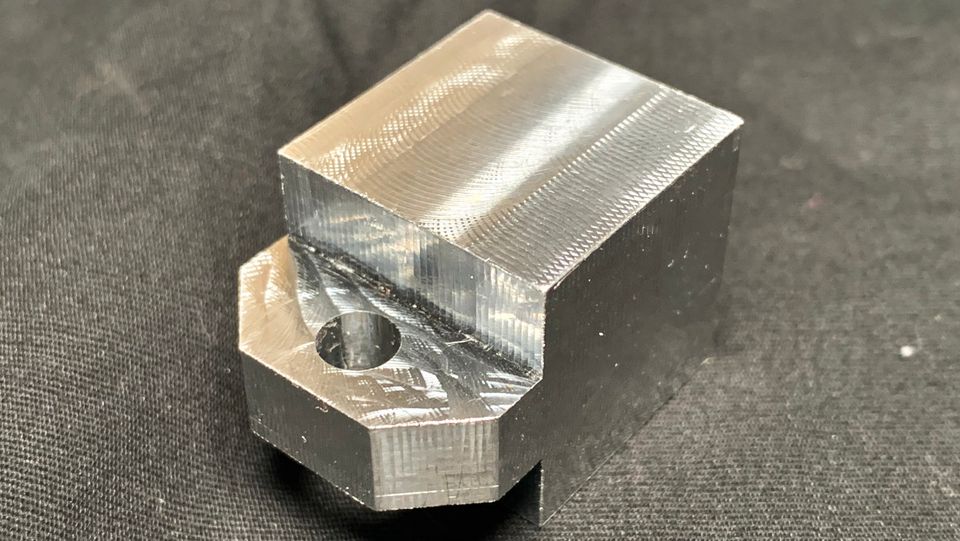

Machining a Weight Block

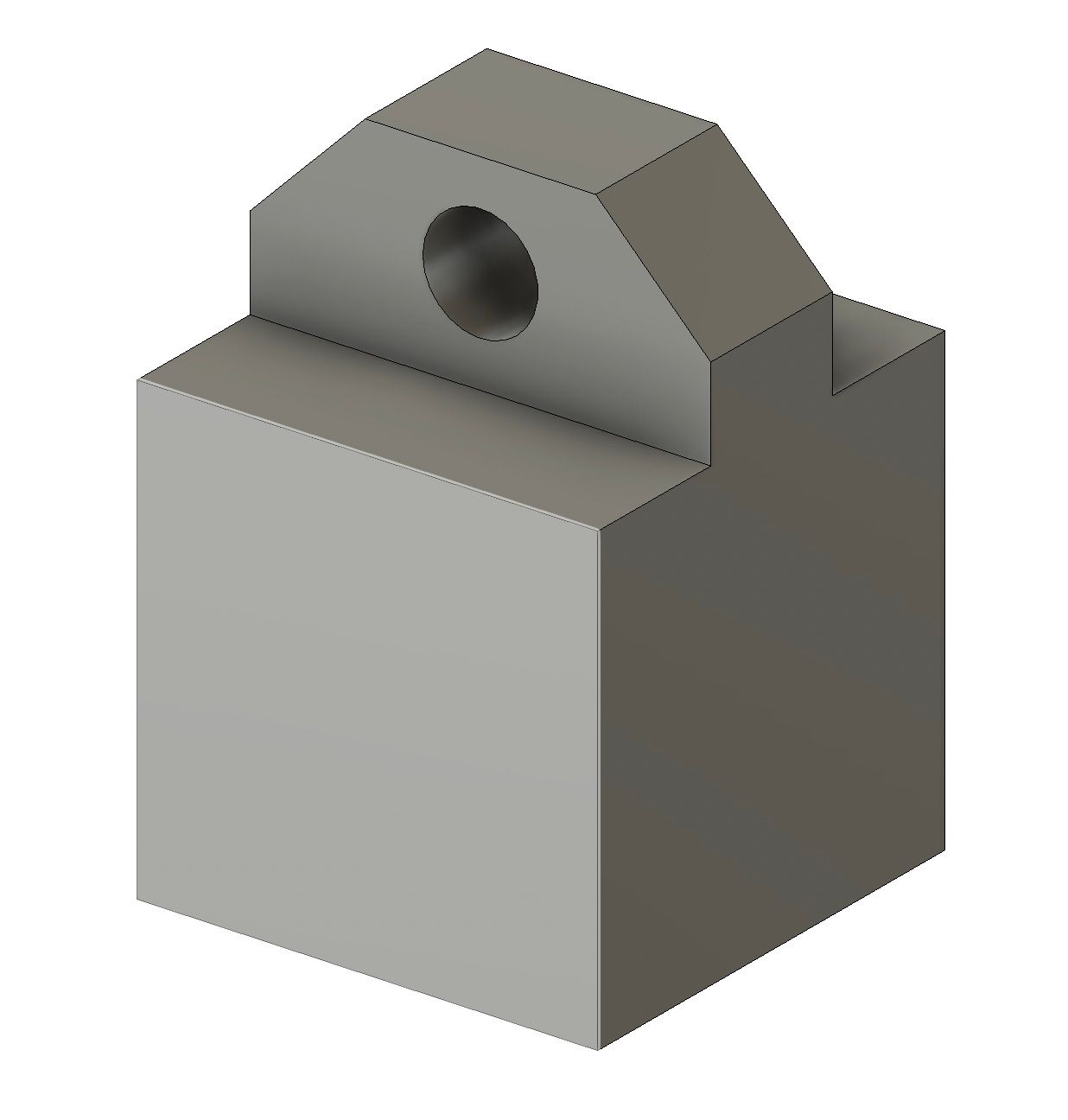

During the writing of an article about the basics of forces, I needed to create weight blocks of identical size from two different materials of different densities. Since I have a CNC milling machine, it made sense to choose 6061 aluminum for one of the blocks. The project was simple but involved enough effort that it feels valuable to share the process here. The design and CAM programing was done in Fusion 360 and machined on my Langmuir MR1 CNC gantry mill.

The surface finish of the block was of little importance for the article demonstration so I opted to go quick and rough. The block was cut from a longer length of 1"x1" extrusion I purchased from a local metal supply company. I cut it with a band saw to about 1"x1"x1.25".

The project took about three hours to design and program (I'm still painstakingly careful when I CNC program... I have yet to crash my machine) and then about an hour to cut from start to finish.